Magnetic Levitation or Maglev Propulsion

Since the discoveries of Nicola Tesla in 1882, and many others who perfected his work, we have known how the Magnetic Levitation technology works. We are convinced that Magnetic Levitation systems must be taken further to be used in advanced high demand applications, such as: Propulsion and Power Generation for home and industries.

For over a decade trains in Japan and in China have been using magnetic levitation technology, traveling at speeds upward of 300 miles per hour. The big difference between a maglev train and a conventional train is that maglev trains do not have an engine, at least not the kind of combustion engine used to pull typical train cars along steel tracks. The engine for maglev trains is rather inconspicuous. Instead of using fossil fuels, the magnetic field created by the electrified coils in the guiding path walls and the track combined to propel the train.

The science of magnetic levitation can also be used to create many other devices such as, but not limited to: home power generators, and as you can see at the above quiet engines for automobiles. And since these generators only consume 20% of the energy they produce to run, that leaves 80% of the energy produced available for powering your house, or running your car. These scientific facts have been kept secret by criminal elites who own banks, which control and own everything else, including oil companies and all other related industries.

Introduction

Maglev systems are becoming a popular application around the globe. Maglev trains are popular in transportation stations in big countries like Germany, China, Japan and the United States of America due to the demand for high-speed transportation, as the general public transportation services become more congested with increase of population. Maglev trains are magnetically levitated trains that traverse in a very high speed, with only electricity being its main source of energy. The train propels forward without any friction from moving mechanical parts. It has many advantages with minor drawbacks.

The basis of maglev trains mechanisms are magnetic levitation. This is achieved with the principal of repulsion and attraction between two magnetic poles. When two magnets have the same poles, it will repel with each other and when it has different poles, the result would be otherwise.

There are currently three known maglev suspension systems. In this project report, we will be covering the basic principals of Electrodynamic Suspension Systems (EDS), Electromagnetic Suspension Systems (EMS) and Inductrack. The three suspension systems each have different characteristics and special features. While EDS and EMS both use only the interaction of magnets and superconductors, Inductrack uses coils on the track underneath the train body. All three suspension systems work under the same principal of magnetic levitation covered in this project report.

The maglev propulsion systems uses the interaction of stators, superconductors and magnets between the railway and the train. It has controls for speed and direction, which are based on electricity.

Magnetic Levitation

Maglev’s levitation is basically based on two simple and fundamental laws of electromagnetic.

• FARADAY’S LAW

• LENZ’S LAW

FARADAY’S LAW:

Faraday's law describes how an electric field can be induced by a changing magnetic flux, or in other words it describes about the induction of electric current.

It states that: "The emf (electromagnetic force) induced in a circuit is directly proportional to the time rate of change of magnetic flux through the circuit."

is the electromagnetic force (EMF) in volts ΦB is the magnetic flux through the circuit (in Webers).

is the electromagnetic force (EMF) in volts ΦB is the magnetic flux through the circuit (in Webers).

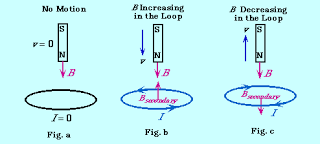

Faraday’s law simply says that, if a closed loop of wire is placed close to a permanent magnet, then electric current can be induced into the wire by moving either the magnet with respect to the coil or vice versa. Hence it is the relative movement between the coil and the magnet that matters (change in flux cutting the loop).

When the magnet is moved toward the loop, the current induced flows in one direction, but when it is moved away, it flows in opposite direction, it indicates that the direction of the current depends on the time rate of change of the field, i.e. if the field is getting stronger or weaker as time progresses. The direction of induced current is further explained by Lenz’s law.

LENZ’S LAW:

Lenz's law describes about the direction of current being induced by magnetic field as described in Faraday’s law.

It states that: “Induced electromotive force generates a current, which flows in such direction as to induce a counter magnetic field that opposes the magnetic field generating the current”.

The induced EMF creates a current that itself creates a secondary magnetic field. This secondary magnetic field also changes with time and thus creates a changing secondary magnetic flux. The secondary flux changes in such a way to oppose the change in flux creating the EMF.

To further understand, consider a coil and permanent magnet as shown in figure. No change in flux means no current induced. Now consider when the north pole of a permanent magnet is pushed into a loop (Fig b) the flux increases. An upwards secondary magnetic field is created that opposes the downward B-field of the magnet, and thus the current in loop must flow counterclockwise in order to create this secondary B-field.

When the magnet is removed from the loop (Fig c), the decreasing B-field in the loop creates a decreasing flux. To oppose this decrease, the current in the loop flows in such a way that tries to sustain the magnetic field. The current now has to flow clockwise in order to create a positive secondary flux that tries to counter acts the decreasing flux due to the with drawl of the permanent magnet.

How is magnetic levitation achieved?

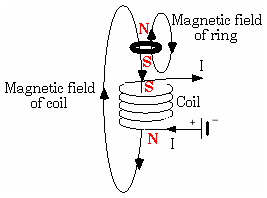

Magnetic levitation can be further understood by considering a current carrying coil. When current flows through the coil, it induces magnetic field. The change in magnetic field in the coil due to the change in current induces Eddy current in the metal ring, which induces magnetic field, as to oppose the field generating it. There repulsive force of the south-south pole (here) lifts the ring.

Magnetic levitation can be further understood by considering a current carrying coil. When current flows through the coil, it induces magnetic field. The change in magnetic field in the coil due to the change in current induces Eddy current in the metal ring, which induces magnetic field, as to oppose the field generating it. There repulsive force of the south-south pole (here) lifts the ring.

There are two types of magnetic levitation.

• Electromagnetic levitation (the ring example)

• Electrodynamics levitation.

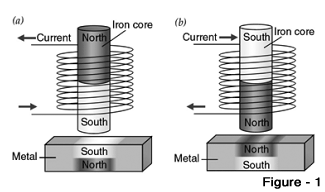

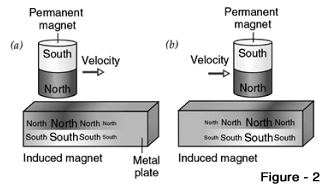

The two figures as given further explain both type of magnetic levitations. Basically both employ same phenomenon, for levitation. In figure a, we have coil wrapped around the iron core, placed over a metal plate. Now when current flows through the coil, iron core is induced with the magnetic field.

This magnetic field as a result induces the magnetic field in the metal, but in opposite direction. Hence both fields repel each other and iron core is lifted upward. In figure b, we have a permanent magnet instead of iron core. When magnetic flux is changed by moving the magnet, it induces the magnetic field in the metal plate.

Thus both methods can be used to achieve levitation.

Maglev Suspension Systems

Electromagnetic Suspensions

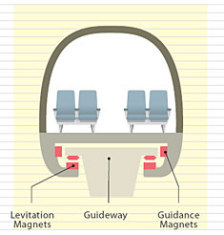

The electromagnetic suspension EMS uses attractive force system to levitate. The train’s levitation magnet will be attracted to the conductors on the underside of the guideway. The attractive force between them will overcome the gravitational force. This will in turn levitates the train on the track.

The electromagnetic suspension EMS uses attractive force system to levitate. The train’s levitation magnet will be attracted to the conductors on the underside of the guideway. The attractive force between them will overcome the gravitational force. This will in turn levitates the train on the track.

The guidance magnets on the other hand guides the train so that the side of the track will not have contact with the train, creating friction and damages the train. The guidance magnets will also guide the train so that it will follow the direction of the guideway track.

From the figure above, we can see that the train is wrapped around the track. Because of this, the EMS train is a safer train and comfortable. The regulated levitation of the train makes the train levitates even when traveling at low speed. The magnetic field intensity inside the passenger compartment is also small so it is safe for passengers with pacemakers or passengers carrying magnetic storage such as credit card or hard disk. Its intensity is comparable to the earth's magnetic field and far below the field intensity of a hair dryer, an electric drill or a sewing machine.

In the event of a power failure, the EMS maglev train is equipped with an emergency battery power supply so that the maglev train will not crash onto the guideway.

The most successful EMS maglev train so far is called the Transrapid system and it is currently being used by the MagLev in Shanghai, China. It is also being used in Germany.

Electrodynamic Suspension

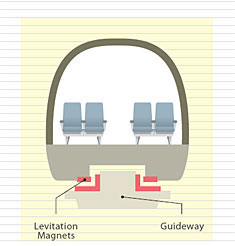

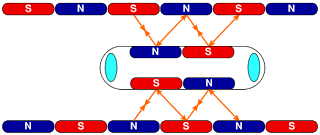

The electrodynamic suspension (EDS) train has been developed by Japanese engineers. It uses magnets that has same polarity (refer to figure above) to create repulsive force between levitation magnet and guideway magnet. This repulsive force then will be high enough to overcome gravitational force and allows it to levitate.

The electrodynamic suspension (EDS) train has been developed by Japanese engineers. It uses magnets that has same polarity (refer to figure above) to create repulsive force between levitation magnet and guideway magnet. This repulsive force then will be high enough to overcome gravitational force and allows it to levitate.

The main difference between EDS maglev train and EMS maglev train is that EDS maglev train use super-cooled, superconducting electromagnets. This superconducting electromagnet can conduct electricity even after the power supply has been shut off for example in the event of a blackout. In the EMS system, which uses standard electromagnets, the coils only conduct electricity when a power supply is present. By chilling the coil at frigid temperatures, Japan’s EDS system saves energy. However, the cryogenic system uses to cool the coils can be expensive.

One potential drawback in using the EDS system is that maglev trains must roll on rubber tires until they reach a liftoff speed of about 62 miles/h (100 km/h). Past the liftoff speed, the train will levitate and the rubber tires will no longer in contact with the guideway. However, Japanese engineer say that the wheels are an advantage if a power failure caused a shutdown of the system. The EDS train is impressively capable to levitate nearly 4 inches (10cm) above the guideway.

Since EDS train will induce a high intensity magnetic field, the passenger section of the train will have to be shielded from the magnetic field or else it will be dangerous for passengers with pacemakers and damages magnetic data storage such as credit cards and hard drives.

Inductrack

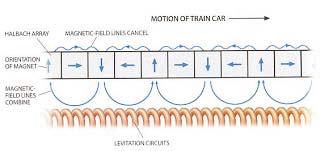

The inductrack is a newer type of EDS that uses permanent room-temperature magnets to produce the magnetic fields insted of powered electromagnets or cooled superconducting magnets. Permanent magnets had not been used before because scientists thought that they would not create enough levitating force. The Inductrack design bypasses this problem by arranging the magnets in a Halbach array. The magnets are configured so that the intensity of the magnetic field concentrates above the array instead of below it. They are made from a newer material comprising a neodymium-iron-boron alloy, which generates a higher magnetic field.

The inductrack is a newer type of EDS that uses permanent room-temperature magnets to produce the magnetic fields insted of powered electromagnets or cooled superconducting magnets. Permanent magnets had not been used before because scientists thought that they would not create enough levitating force. The Inductrack design bypasses this problem by arranging the magnets in a Halbach array. The magnets are configured so that the intensity of the magnetic field concentrates above the array instead of below it. They are made from a newer material comprising a neodymium-iron-boron alloy, which generates a higher magnetic field.

The track is actually an array of electrically-shorted circuits containing insulated wire. In one design, these circuits are aligned like rungs in a ladder. As the train moves, a magnetic field the repels the magnets, causing the train to levitate.

There are two Inductrack designs: Inductrack I and Inductrack II. Inductrack I is designed for high speeds, while Inductrack II is suited for slow speeds. Inductrack trains could levitate higher with greater stability. As long as it's moving a few miles per hour, an Inductrack train will levitate nearly an inch (2.54 cm) above the track. A greater gap above the track means that the train would not require complex sensing systems to maintain stability.

The Inductrack II design incorporates two Halbach arrays to generate a stronger magnetic field at lower speeds.

As of now, there is still no commercial version of inductrack or full scale system prototype.

Magnetic Levitation or Maglev Propulsion

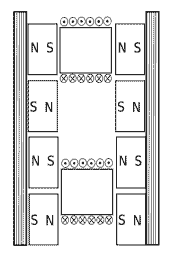

An EMS system can provide both levitation and propulsion using an on board linear motor.

An EMS system can provide both levitation and propulsion using an on board linear motor.

The polarity of the stators (Figure 1) at the track will quickly change its polarity continuously to move the Maglev train. Stators at the sides are excited sequentially. The electromagnets onboard 'chase' the current forward along the track. The continuous magnetic field moving forward. Speed controlled by frequency of alternating current.

Electromagnetic Suspension Systems (EMS)

EDS systems can only levitate the train using the magnets on board, not propel it forward. As such, vehicles need some other technology for propulsion. A linear motor (propulsion coils) mounted in the track is one solution. Over long distances where the cost of propulsion coils could be prohibitive, a propeller or jet engine could be used.

The process of propulsion for EDS is same as EMS except that the stators will stop for a moment after polarity change. Referred as "pull- then neutral- then push” system. Coils or aluminum sheet at the sides. The direction of current of the particular segment is reversed. Polarity of that segment changes which causes repulsion.

Propulsion coils on the guideway are used to exert a force on the magnets in the train and make the train move forward. The propulsion coils that exert a force on the train are effectively a linear motor. The linear motor in the guideway functions just like a conventional electric motor with its stator cut open and stretched out over the length of the guideway. Instead of a magnetic rotary field, the current in the windings generates a magnetic field of travelling waves, which pulls the vehicle without contact. By changing the intensity and frequency of the driving current, speed and thrust can be continuously adjusted. When the motor is operated as a generator, the direction of the energy flow is reverted and used for contactless braking.

An alternating current flowing through the coils generates a continuously varying magnetic field that moves forward along the track. The frequency of the alternating current is synchronized to match the speed of the train. The offset between the field exerted by magnets on the train and the applied field create a force moving the train forward.

A linear motor or linear induction motor is essentially a multi-phase alternating current (AC) electric motor that has had its stator "unrolled" so that instead of producing a torque (rotation) it produces a linear force along its length. The most common mode of operation is as a Lorentz-type actuator, in which the applied force is linearly proportional to the current and the magnetic field (F = qv × B).

Many designs have been put forward for linear motors, falling into two major categories, low-acceleration and high-acceleration linear motors. Low-acceleration linear motors are suitable for maglev trains and other ground-based transportation applications.

The force is produced by a moving linear magnetic field acting on conductors in the field. Any conductor, be it a loop, a coil or simply a piece of plate metal, that is placed in this field will have eddy currents induced in it thus creating an opposing magnetic field. The two opposing fields will repel each other, thus forcing the conductor away from the stator and carrying it along in the direction of the moving magnetic field.

The force is produced by a moving linear magnetic field acting on conductors in the field. Any conductor, be it a loop, a coil or simply a piece of plate metal, that is placed in this field will have eddy currents induced in it thus creating an opposing magnetic field. The two opposing fields will repel each other, thus forcing the conductor away from the stator and carrying it along in the direction of the moving magnetic field.

Free body diagram of a U-channel linear motor. The view is perpendicular to the channel axis. The two coils at center are mechanically connected, and are energized in ‘quadrature’ (with a phase difference of 90° (π/2 radians)). If the bottom coil (as shown) leads in phase, then the motor will move downward (in the drawing), and vice versa.

Magnetic Levitation or Maglev Track

The magnetized coil running along the track, called a guideway, repels the large magnets on the train's undercarriage, allowing the train to levitate between 0.39 and 3.93 inches (1 to 10 cm) above the guideway. Once the train is levitated, power is supplied to the coils within the guideway walls to create a unique system of magnetic fields that pull and push the train along the guideway. The electric current supplied to the coils in the guideway walls is constantly alternating to change the polarity of the magnetized coils. This change in polarity causes the magnetic field in front of the train to pull the vehicle forward, while the magnetic field behind the train adds more forward thrust.

Maglev trains float on a cushion of air, eliminating friction. This lack of friction and the trains' aerodynamic designs allow these trains to reach unprecedented ground transportation speeds of more than 310 mph (500 kph), or twice as fast as Amtrak's fastest commuter train. In comparison, a Boeing-777 commercial airplane used for long-range flights can reach a top speed of about 562 mph (905 kph). Developers say that maglev trains will eventually link cities that are up to 1,000 miles (1,609 km) apart. At 310 mph, you could travel from Paris to Rome in just over two hours.

Maglev trains float on a cushion of air, eliminating friction. This lack of friction and the trains' aerodynamic designs allow these trains to reach unprecedented ground transportation speeds of more than 310 mph (500 kph), or twice as fast as Amtrak's fastest commuter train. In comparison, a Boeing-777 commercial airplane used for long-range flights can reach a top speed of about 562 mph (905 kph). Developers say that maglev trains will eventually link cities that are up to 1,000 miles (1,609 km) apart. At 310 mph, you could travel from Paris to Rome in just over two hours.

Germany and Japan are both developing maglev train technology, and both are currently testing prototypes of their trains. (The German company "Transrapid International" also has a train in commercial use -- more about that in the next section.) Although based on similar concepts, the German and Japanese trains have distinct differences. In Germany, engineers have developed an electromagnetic suspension (EMS) system, called Transrapid. In this system, the bottom of the train wraps around a steel guideway. Electromagnets attached to the train's undercarriage are directed up toward the guideway, which levitates the train about 1/3 of an inch (1 cm) above the guideway and keeps the train levitated even when it's not moving. Other guidance magnets embedded in the train's body keep it stable during travel. Germany has demonstrated that the Transrapid maglev train can reach 300 mph with people onboard.

The propulsion system of the superspeed maglev system is installed in the guideway in the form of a linear motor. This "guideway motor" has two big advantages: firstly, the vehicle is much lighter, and secondly, the driving power is flexible. This means that in up-grade or acceleration sections more power is installed in the guideway than in sections where the route runs at grade.

Additionally, a lot of energy is saved because only that section of the linear motor on which the vehicle moves is powered. Moreover, this prevents two vehicles from being in the same section at the same time and absolutely leaves no chance of trains meeting on the same track.

The double-track guideway consists of beams made of concrete or steel and is installed at grade or elevated, so the guideway can be adapted to any terrain.

References

- http://en.wikipedia.org/wiki/Magnetic_levitation_train

- http://www.virtualsciencefair.org/2004/leun4m0/public_html/Howitworks.html

- http://science.howstuffworks.com/maglev-train2.htm

- www.howstuffworks.com/maglev-train.htm

- www.gizmohighway.com/transport/maglev_train.htm

- http://faculty.washington.edu/jbs/itrans/maglevq.htm

- www.magnet.fsu.edu

- http://amasci.com/maglev/train.html

- http://www.monorails.org/tMspages/MagMono.html

- http://www.maglev2000.com/works/how-02-b.html

- http://home.wangjianshuo.com/archives/20041012_inside_pudong_airport_maglev_train.htm

- http://www.googobits.com/articles/2876-maglev-trains-flying-without-wings.html

- http://news.bbc.co.uk/2/hi/business/7011932.stm

- http://www.magnet.fsu.edu/education/tutorials/magnetacademy/superconductivity101/maglev.html

- http://www.21stcenturysciencetech.com/articles/Summer03/maglev2.html

- http://www.maglev2000.com/apps/applications.html

- http://thetransitcoalition.us/MiscInfo/InterviewComWu-Wenhui.htm

- http://www.iit.edu/~okebaba/

- http://magnetbahnforum.de/index.php?en_facts

- http://www.railserve.com/maglev.html

- http://inventors.about.com/library/inventors/blrailroad3.htm

- https://www.llnl.gov/str/Post.html